|

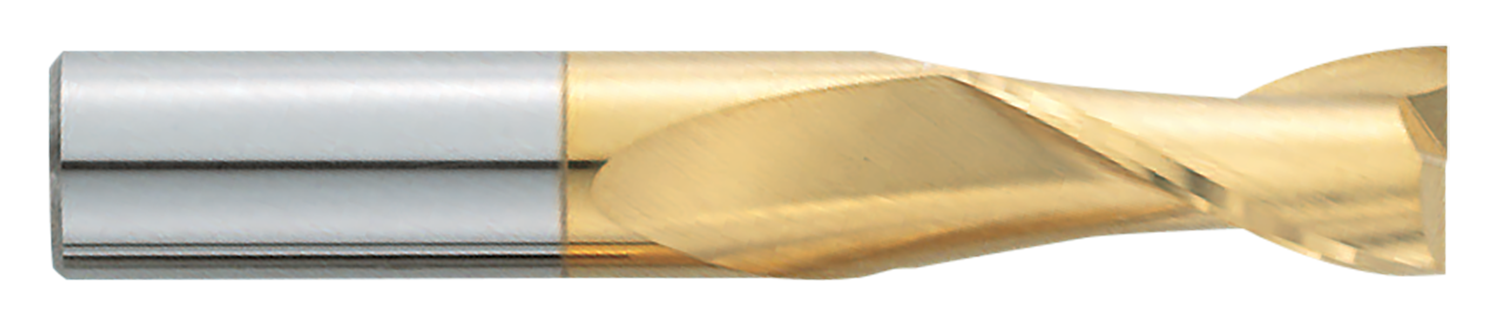

TiN (Titanium Nitride) |

| General purpose coating – low heat resistance. Good lubricity. |

|

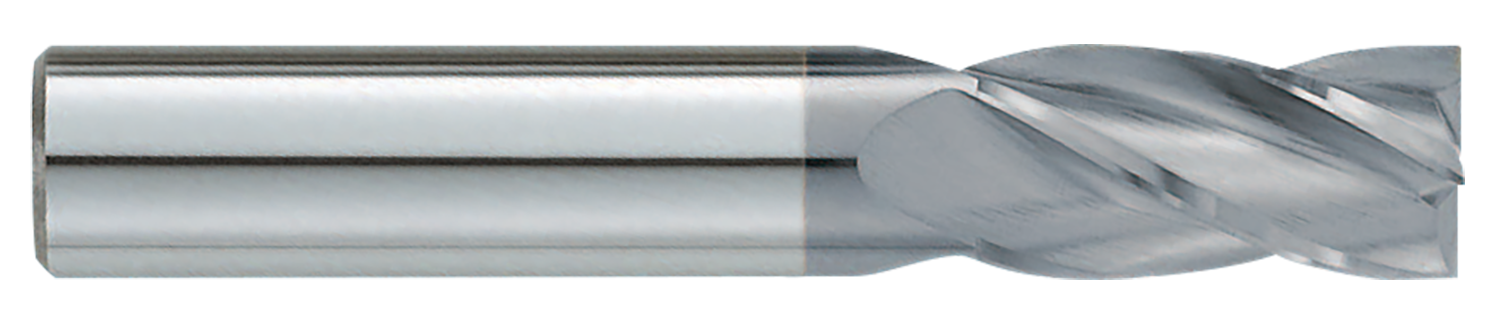

TiCN (Titanium Carbonitride) |

| Good abrasion resistance. Recommended for aluminum, brass, and bronze applications. Low heat resistance – good lubricity. |

|

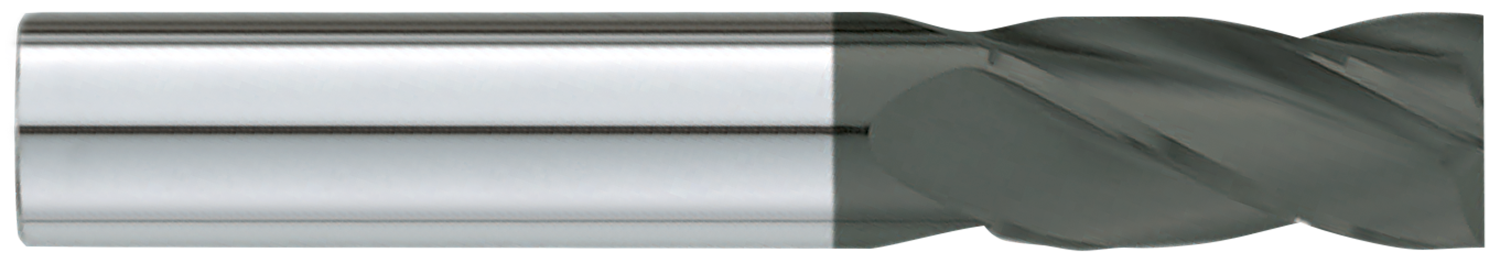

TiAlN (Titanium Aluminum Nitride) |

| Multi-layer coating with good thermal stability for increased speeds and feeds. For semi-dry to dry cutting of most steels, high-nickel alloys, stainless steel and cast iron. Excellent heat resistance, good lubricity. For materials that are 40Rc and under. |

|

AlTiN (Aluminum Titanium) |

| A single-layer coating whose hardness, oxidation resistance and thermal stability were optimized for material hardness above 38Rc and high-speed machining of materials that are difficult to work (titanium alloys, Inconel). |

|

ALUMASTAR® (Titanium Diboride – TiB2) |

| A thin film coating with a low affinity for aluminum, ideal for machining aluminum alloys. The resistance to adhesion of aluminum allows higher speeds or feeds. Coating thickness is intentionally kept lower in order to maintain a sharp edge. |

|

CRYSTALLINE DIAMOND (CVD) |

| Improved productivity in composites. Excellent choice for cutting graphite and fiberglass. Can be added to a special for milling or drilling applications. |

|

AlCrN (Aluminum Chromium) |

| Aluminum Chromium-based coatings have excellent wear resistance, thermal shock stability, and hot hardness. Well suited for Titanium, Inconel, and carbon fiber. |

|

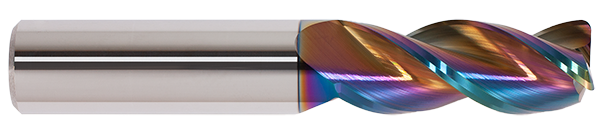

DURANA (AlTiN-based with TiSiXN) |

| A combination of AlTiN-based and TiSiXN layers. Has a high degree of ductility and superior abrasive wear resistance even at extreme service temperatures, resulting in vastly improved performance during demanding machining operations and longer tool service life. |

|

ALTINOS (AlTiN-based) |

| Highly wear resistant, even at high operating temperatures, making it particularly beneficial even up to HRC 56. With its perfectly smooth surface, this coating offers significant performance advantages such as optimum chip removal and reduced built-up edge formation. |

|

ALCRONOS (AlCrN-based) |

| Considerably less prone to built-up edge formation. Its revolutionary smooth coating, with excellent adhesion to the substrate, ensures outstanding surfaces and high production quality, especially in ductile alloys like 300 series stainless and steels up to HRC 50. |