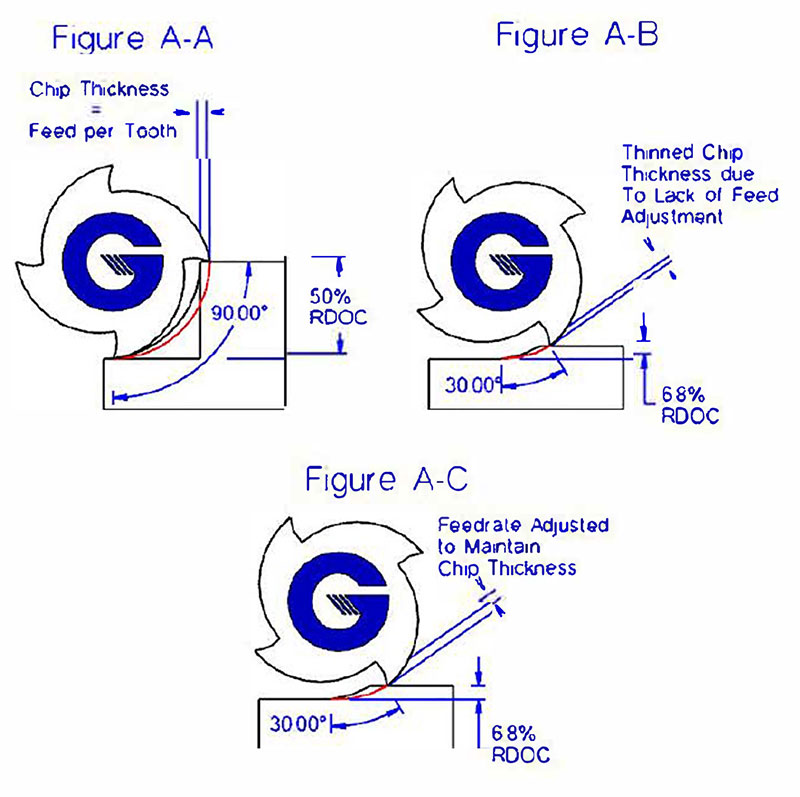

Chip Load (or Maximum Chip Thickness) is one of the most important parameters for achieving a stable and productive milling process. Radial chip thinning occurs when the width of cut is less than 50% of the cutter diameter. Examining from a top view, when feeding an endmill at 50% radial engagement (Figure A-A), the chip thickness holds true to the feed rate programmed. Observing the exact same feed rate when utilizing a lighter radial engagement (Figure A-B), the tool now results in a “thinned chip”. Utilizing a chip thinning calculator to adjust for the reduced cutter engagement (Figure A-C), the feed rate is increased to maintain a contestant chip thickness relative to the radial depth of cut. Once the machining parameters are adjusted, the performance of the tooling will increase along with reduced cycle times and increased metal removal rates.